Trained Safety Officer Program

PDF of the Trained Safety Officer Program

Introduction (2012 Revision):

It has been over a decade since the NAR’s Trained Safety Officer (TSO) program was last revised. NAR policies, regulations, and technologies have changed during that period. This revision updates the safety officer guidelines to reflect those changes.

Model rocketry was created in the late 1950’s as a means by which non-professional individuals could build and fly their own rocket powered models. The hobby was structured to safely pursue an activity that has a potential for personal injury and property damage. The use of manufactured motors to minimize the mixing and handling of propellants was a major factor in model rocketry’s safety success. Safety procedures for the construction and operation of the models, based on aerospace industry practices, were another factor in this excellent safety record.

Hobby maturity and technology advancements permitted the use of more powerful motors and more sophisticated models. High power rocketry describes the step beyond model rocketry. Safety procedures for high power rocketry evolved from model rocketry. This document augments those safety procedures with practical guidance for individuals experienced in model rocketry and familiar with high power rocketry. The intent of this guidance is to assist individuals in performing safety officer functions on a high power rocket range. This guidance is based on experience, regulatory documents (e.g. FAA FAR Part 101), and codified practices (e.g. NFPA 1127). Note that regulatory or codified practices shall supercede guidance in this document if conflicts occur.

The primary safety officers are the Range Safety Officer (RSO) and the safety check-in officer. The RSO is responsible for safe operation of the rocketry range. The RSO shall have the final authority to approve the launch of a model. The RSO may appoint deputy RSO’s to assist in operating the rocket range. The deputy RSO’s have the same authority as the primary RSO to approve the launch of a model. The safety check-in officer is responsible for verification of the model flightworthiness. He will inspect the models for structural integrity, systems condition (e.g. recovery system, motor restraint), motor certification, and dynamic properties (e.g. center of gravity, center of pressure).

The Launch Control Officer (LCO) position, while contributing to range safety, responds to launch consent from the RSO. That consent may be either permission to start the countdown or to initiate the launch at T-0. The LCO is an extra set of eyes monitoring launch conditions and assists the RSO in assuring range safety.

Participants in this program will be required to complete tasks relevant to range safety. Individuals will share safety critical range positions with a mentor. Individuals performing mentored RSO or safety check-in functions must possess a high power certification (Levels 1, 2, or 3).

Mentors will be individuals who are both generally acknowledged to be competent in the safety critical roles and are currently high power certified at Level 2 or Level 3 by either the NAR or Tripoli Rocket Association (TRA). Mentors will observe and advise the participants while they apply suggested guidelines to real world situations.

The objective of the TSO program continues to be the safety education of NAR members by exposing them, with guidelines and mentors, to “real world” situations. This program cannot expose its participants to every situation they may experience as safety officers and that is why many of the less common safety officer tasks have been removed. Instead, individuals who complete the TSO program are asked to continue their participation in safety officer roles to both gain personal knowledge and to mentor new participants in safety officer positions. Your mentors have not “seen it all” and they will be working with you to learn and promote safety within the NAR.

Requirements:

1.0 Specific Safety Check-in Officer Tasks Description

A) 15 high power check-ins required (Level 1 or 2)

B) 3 of the above models include electronic recovery deployment systems

2.0 Range Safety Officer Tasks Description

A) 10 high power launches required (Level 1, 2, or 3)

B) 1 launch site evaluation required

Safety Check-in Officer Guidelines:

The items below offer guidance for the acceptance and rejection of models presented for inspection. In addition to the inspection, question the modeler about his model. Ask him if he has any worry areas and what, if anything, he has done to minimize that worry. Other questions may be directed towards specific features of the model. Ask if he has flown the model before with the installed motor and recovery system. If, for example, electronic recovery or staging are being attempted for the first time ask the modeler how he tested their operation prior to flight. If a lack of knowledge or skills is evident from the conversation then consider performing a more extensive inspection of the model.

The guidance provided below addresses the majority of high power models a check-in officer is likely to encounter. High performance models, typically models capable of supersonic flight or altitudes in excess of 15,000 feet, have specialized requirements commensurate with their performance capabilities. This program does not attempt to address unique design features required by high performance models.

Item A1 reminds check-in officers of their obligation during model check-in. Items A2 through A4 provide administrative guidance. Items A2 and A3 are necessary to assure compliance with Consumer Product Safety Commission (CPSC), NFPA 1125, and NFPA 1127 user requirements. Item A4 guidance is intended to assure compliance with the Federal Aviation Administration (FAA) Part 101 requirements.

A1) Check-in officers have no obligation to allow models to fly. If, in their best judgement, a model is unsafe then it shall not pass through check-in nor if launch conditions are unsafe shall a launch be permitted. If technical doubts are present during the check-in inspection the safety check-in officer should consult with the range safety officer(s). The decision by any range safety officer may not be appealed. The range safety officers may consult among themselves or with other technically competent individuals prior to making a decision. Modeler’s excuses, including long drives and event entry expenses should not compromise the safety officer decisions.

A2) Is the modeler under 14 years old? If yes, the modeler cannot legally use high power motors, reloadable motors of any power class, “G” motors, or hybrids. “G” motors and reloadable motors may be used if the individual is accompanied by a parent or legal guardian.

Is the modeler under 18 years old? If yes, the modeler cannot legally use reloadable motors of any power class, “G” motors, or hybrids. “G” motors and reloadable motors may be used if the individual is accompanied by a parent or legal guardian. A modeler between 14 and 17 years of age may launch a high power rocket if the individual has completed certification under the NAR’s Junior High Power Certification.

A3) Is the modeler certified to the power level being flown? Ask to see his membership card to verify the certification level. Note that the NAR recognizes the high power certification for individuals certified by the Tripoli Rocketry Association and Canadian Association of Rocketry. Make sure that the membership card is current. Note that some events will verify the certification level at registration. In that case, the person will have event identification showing the certification level. Individuals flying models meeting the following criteria will require high power certification:

a) Launches models containing multiple motors with a total installed impulse of 320.01 Newton-seconds or more, or

b) Launches models containing a single motor with a total installed impulse of 160.01 Newton-seconds or more, or

c) Launches rockets that weigh more than 53 ounces (1500 grams), or

d) Launches models powered by rocket motors not classified as model rocket motors per NFPA 1122, e.g.:

- Average thrust in excess of 80.0 Newtons

- Contains in excess of 4.4 ounces (125 grams) of propellant

- Hybrids

Note that some “F” and “G” motors fall into this category.

A4) Does the model fall within the FAA limitations? Within the sport rocketry hobby the FAA recognizes two classes of rockets:

Class 1 – Model Rocket; a model rocket has no more than 125 grams (4.4 ounces) of propellant and weighs no more than 1500 grams (3.3 pounds) at launch. Class 1 rockets have no requirements for waivers, authorization, or notification.

Class 2 – High Power Rocket; a high power rocket exceeds the model rocket propellant and launch weigh limits. In addition, a Class 2 rocket does not have a total impulse exceeding 40,960 Newton-seconds. Class 2 rockets have requirements for notification, waivers, and/or authorizations prior to commencing flight operations. Notification requirements are discussed under the RSO section.

The waiver or authorization will specify a maximum altitude for flights. Verify with the event director or RSO that a waiver has been approved prior to accepting these models. Models must be weighed and motor propellant weight determined to verify that the model needs a waiver for legal flight. The performance of the model must be evaluated to determine compliance with the waiver altitude limit. Tables listing the motor type and model diameter may be available to indicate a minimum weight for the model. Models under the minimum weight must add ballast or reduce power to stay within waiver limits.

Participants may provide computer printouts or cite computer simulations identifying the anticipated maximum altitude for the model. Model configurations that have not previously flown and are predicted to exceed 90% of the waivered altitude should not be permitted to fly on the basis of a single computer simulation run. The logic is that there are too many variables (e.g. motor total impulse, delay duration, site temperature) affecting model performance for a single computer simulation to be a credible source of data. Recommended procedures are computer simulations that manually or automatically perform some form of Monte Carlo analysis or computer simulations that have been validated by flight data for the model.

Modelers should be able to identify the values for parameters used for the simulation. The drag coefficient (CD) is one of the more important parameters. When estimating performance, be conservative by using a lower value for the drag coefficient (CD). Most airframes will have a CD between 0.65 and 0.75. Use a CD value between 0.45 and 0.50 for a conservative estimate of airframe performance. Computer software may also be available on the field to estimate performance.

The source material for this section is the Federal Aviation Regulations (FAR) Part 101, Subpart C. The information is available on-line

Items A5 through A9 concern the rocket motor(s). The NAR safety code requires the use of certified rocket motors. Item A4 addresses this requirement. Items A5 through A7 are intended to verify the correctness of the motor choice and to identify potential safety hazards associated with the igniter. Items A8 and A9 address areas generally associated only with reloadable motors.

A5) Is the motor certified? Certification lists are available on the Internet or in publications from the certifying organizations. Verify the motor certification status by consulting the certification lists. Note that certification status may not extend to all delays within a motor type.

A6) Is the motor or motors adequate to safely fly the model? If available, consult the manufacturer’s recommended liftoff weight. Model drag and weather conditions should be considered. High drag models (caused by basic model design, poor finish) will not go as high as streamlined models. Low average thrust motors in windy conditions allow more weathercocking of the model. The altitude may be limited due to weathercocking and the delay may be too long. Remember that motors with longer delays have lower recommended liftoff weights than the same motor with a shorter delay. If still in doubt, ask the modeler for his performance predictions and the prediction method for the model.

A7) Will the model have sufficient lift-off performance to achieve adequate velocity for stability before it leaves the launch pad? As a quick calculation divide the motor’s average thrust in Newtons by 25. Use the sum of the average thrusts for the motors ignited at launch in a cluster. The answer is the maximum lift-off weight in pounds. Using the above formula the maximum liftoff weight for an H123 powered model would be approximately 5 pounds.

The above formula converts Newtons to pounds by dividing the average thrust by 5 (the actual conversion is 4.45 so a margin of safety is built in). A thrust to weight ratio of at least 5 is desired. Multiplying the 5 by 5 gives 25. This quick check does not take into account the actual thrust curve of the motor. Calculations or simulations should be referenced for a more accurate determination of lift-off performance.

A7) Is the igniter a low current type? Flash bulbs and electric match current requirements are low enough that some launch systems my set them off with continuity power. Verify with the RSO or LCO whether the launch system is “flash bulb safe”. Annotate flight cards if required to show the presence of a low current igniter.

A8) Ask the modeler if he is using the motor ejection charge. If he is, verify that he installed the black powder. Also, some motors rely on a tape disk to retain the powder in its cavity. Disks with dry adhesive or lubricant contamination on the forward face of the cavity may reduce the paper disk adhesion. Deceleration forces may cause the paper disk to come free and disperse the black powder. This will cause an ejection failure. It is suggested that the modeler backup the paper disk with masking tape around the edge to prevent it from coming free.

A9) Some motor manufacturers have permitted modification of their motors from the sold configuration. Shortening of the ejection delay is an example of a motor modification that is documented by manufacturers. If a motor configuration appears to have had modifications not approved by the manufacturer ask the flyer to supply manufacturer’s documentation that the change is permitted.

Items B1 through B8 cover the inspection of the basic model structure and recovery system. The check-in officer will need to handle the model during this phase of the inspection. Ask the model builder if there are any safety hazards, e.g. electronic systems, which may be activated while handling the model. The check-in officer needs to use his judgement when pulling and pushing on model parts; the effort needs to be sufficient to find marginal installations or construction but not so great as to damage a properly built model.

B1) Examine all “slip-fits”, e.g. nosecone or payload shoulder, which are intended to separate in flight.

Turn the model nose down. It is unacceptable if the nosecone (or payload) can separate under their own weight. If it does, the nosecone (or payload) may “drag separate” just after motor burnout. Drag separation typically occurs at the highest velocity; the effect is often recovery system failure from excessive loads. A loose nose cone (or payload) can be tightened by the addition of tape to the shoulder.

Does the nosecone (or payload) slide free without excessive effort? A tight nosecone (or payload) can be caused by several problems. Paint overspray in the tube or on the shoulder may cause stickiness in the sliding area. A light sanding or a dusting with talcum powder can reduce the stickiness or remove the overspray. A burr may also form at the edge of the body tube. Again, a light sanding can correct the problem.

Check that the nosecone, if used as part of a payload section, is firmly installed. The object is to prevent loss of the nosecone and the payload contents in flight.

Consider the comment “it’s flown before” with caution. Temperature and humidity affect the fit of airframe parts (parts swell or contract, finishes may soften in the heat). A smooth fit in an Arizona winter may become a test of muscle and patience in an Alabama summer.

The use of shear pins avoids the possibility of drag separation from slip fits during flight. One option for a shear pin is a #2 nylon screw (2-56). No less than two shear pins should be used because it’s possible the nosecone can cock to one side and jam if only one is used. Also, look for elongation of the shear pin holes. Elongated shear pin holes may allow the shear pin to bend as opposed to shearing; an increase in the force required to shear the pin will occur under this circumstance. If the model uses shear pins, ask the modeler if he has tested his ejection system to know that he has properly sized his ejection charge(s). On-line information and calculators for shear pins are available at the following URL: https://www.info-central.org/?article=303.

B2) Examine the launch lugs and rail guides. Are the launch lugs and rail guides firmly attached to the model without evidence of cracking in the joints or looseness? Are the lugs adequately sized for the model? Suggestions are 1/4″ lugs for models up to 5 pounds, 1/2″ lugs for models up to 15 pounds, and rail buttons for 1010 or 1515 rails for models exceeding 15 pounds. Single launch lugs should be at least 6 inches long and mounted at the model’s CG. Two lugs or guides, each spaced a minimum of 2 body tube diameters from the CG are preferred. The separated lugs or guides are preferred because they better resist rotation (from winds) of the model on the launch rod. Rotation of the model on the launch rod may cause binding during launch.

Check the lugs and guides for paint buildup or burrs inside the lug(s). Paint or burrs may cause binding on the launch rod. A rolled sheet of sandpaper can be used to remove burrs or paint from inside launch lugs.

B3) Examine the fins. Are the fins mounted parallel to the roll axis of the model? Attempt to wiggle the fins at their tips. There should be no movement and minimal deflection. If the fins deflect is the fin material appropriate for the model? Models powered by H, I, or J motors should use 1/8″ plywood or fiberglass at a minimum. Higher powered models and high aspect ratio fins (large fin span versus fin chord) require additional strength to resist launch loads and possible flutter problems. Laminated or built-up fins should be checked for delaminations. Bubbles may indicate delaminations. Tapping the fin with a heavy coin (e.g. half-dollar) will give a “dead” thud if a delamination is present. Examine the fin roots for cracks; minor “hairline” cracks may be acceptable if the fins are not loose or if the fins are mounted using “through the wall” construction. Check the fins for warpage; there should be little, if any, warpage.

B4) Examine the engine installation. Verify, if possible, that the engine is what the flight card indicates. If in doubt, ask that the engine be removed from the model. Pull on the motor to make sure it is firmly restrained in the model. If the motor is friction fitted then it should not move when strongly pulled. A positive means of engine retention, e.g. motor spring clip, bolted washers, or threaded retainer is preferred. Verify that the motor cannot deflect the retention device and then eject. A wrap of tape around motor spring clips to maintain contact against the motor is suggested.

B5) Can the motor “fly through” the model? Push on the nozzle end of the motor. The motor should not move forward in its mount nor should the mount move within the model. Try to determine the type and quantity of adhesive used in construction. Any evidence of “hot melt” adhesives should make the model suspect. Motor mounts should typically be mounted with epoxy adhesives with a sufficient quantity to form fillets at the centering ring to body tube joints.

B6) Is the model stable? Find the CG (center of gravity) of the flight ready model (motors installed, recovery system packed) by finding the model balance point. Where is the CG relative to the leading edge of the fins? On a single staged model with only a rear set of fins the CG should typically be forward of the forward root edge of the fins.

Canards, wings, forward swept fins, and strakes will require the CG to be further forward. Multi-staged models must be evaluated for each stage. Ask the modeler to show the CP (center of pressure) location on the model (and less each stage for a staged model). Request to see the calculations if in doubt. The CG must be a least one body tube diameter forward of the CP in each flight phase. Note that a subscale model may, in most cases, also be flown to show stability of the full size model.

Keep in mind that recovery system components, e.g. risers and parachutes may shift rearwards during flight. This will shift the CG aft and may destabilize the model.

Hybrid powered models must also be examined carefully for stability. Unlike most solid fueled models the CG of a hybrid model may actually move aft during flight. The rearward CG shift may destabilize the model. To be conservative, determine the CG of a hybrid model with the solid fuel component in place but without the oxidizer loaded.

B7) Ask the modeler about the recovery system and if in doubt about its adequacy ask to inspect the recovery system.

Pull on the shock cord several times. The shock cord must not be cracked, cut, frayed, or burnt. Discoloration from ejection operation is typically not a problem. Make sure that the shock cord is securely mounted in the model. Make sure any knots in the recovery system will not loosen or slip. Note that “shock cords” are a holdover from model rocket “technology”. The separation and parachute deployment forces in larger high power rockets may be beyond the strength capabilities of most elastic materials. If a shock cord is used its length should be at least two to three times the length of the model. It is preferred in larger high power models to control the deployment of the parachute system to minimize separation and deployment loads. Higher strength materials with limited “give”, e.g. tubular Nylon or Kevlar, may be used to control some of the separation loads. Better still is the use of parachute bags, folding, and reefing techniques to control the opening of the parachute. “Staged” parachute deployments using progressively larger parachutes are another approach to control recovery loads.

Recovery system hardware, including screw eyes and swivels, needs to be strong enough for recovery loads and mounted to solid structure. All fasteners should be inspected for tightness. Inspect “quick links” to verify that they are not likely to pull apart under recovery loads. The “eye” in a screw eye should be welded or brazed closed for heavier models to prevent opening of the eye from recovery system loads.

Is the parachute sufficiently large to safely recover the model? Ask the modeler how large his parachute is. Ask how the parachute size was determined and what the planned descent rate is. A maximum descent rate of 15 to 20 feet per second is suggested. Remember that cross form parachutes need to be larger to have the same effectiveness as round parachutes. Several parachute sizing programs and applets are available on the internet (e.g. https://www.rockethead.net/parachute_size.htm).

Is parachute protection from the ejection charge adequate and nonflammable? Is non-flammable, bio-degradable (no fiberglass) wadding being used?

Verify that the parachute is undamaged including no loose suspension lines and no tears or burns which may spread during recovery.

Ask if the model uses a metallic mesh as a baffle to cool the ejection charge. Metallic mesh baffles can become clogged with ejection charge debris and block the ejection charge. This can be a problem on a model that has completed many flights. Ask the modeler if he knows his baffle is not clogged.

B8) Does the booster section have a vent hole? Typically, a 1/8 to 3/16 inch hole is drilled in the booster section just behind the nosecone or payload shoulder area. Note that multiple and/or larger holes may be required for larger (5.38 inch and larger diameter) airframes. This hole is intended to vent the rocket internal pressure to the outside. It is recommended practice on high performance (high altitude) models because it prevents the internal pressure from prematurely separating the nosecone or payload section.

Items C1 through C6 concern check-in items peculiar to cluster models.

C1) If the model is a cluster look for any open holes between the motor mounting tubes. Are the holes sealed to prevent ejection charge gases from venting out?

C2) If black powder and composite motors are mixed in a cluster are the composite motors the first to be ignited? Composite motors are harder to ignite than black powder. The model must not separate from the ignition system before the composite motors are ignited.

C3) Are the motor igniters for the cluster to be wired in parallel and not in series (igniters should not be installed in high power models until the model is at the launch pad)? Check for shorts that may prevent igniter function.

C4) Are the igniters “matched”? Igniters having different current requirements may not light at the same time. Igniters that light quickly may ignite their rocket motors prior to ignition of other motors in the cluster. The model may leave the pad before all the motors are started.

C5) If thermalite is used for air-starts is the thermalite protected from accidental ignition from a “chuffing” motor? Are igniters adequately secured to prevent them from falling out from acceleration forces?

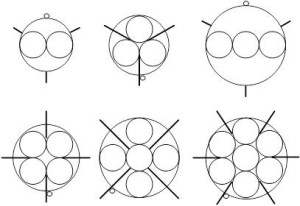

C6) Examine where the launch lugs are mounted relative to the motor position. The launch lug position can provide some additional margin of safety in the event of partial ignition of the cluster. Suggested launch lug positions are shown in the following figure.

Items D1 through D6 concern the use of radio control equipment.

D1) If radio control is used for flight functions, is the operating frequency in the 27, 50, 53, or 72 megahertz bands? 72 megahertz radios using the “old” 2 color flag system for frequency identification are not legal. 75 megahertz frequencies may not be used for flight functions. Note that 27 megahertz usage, while legal, is discouraged due to the possible interference from citizen band (CB) radios.

Recent radio control systems utilize 2.4 gigahertz spread spectrum or frequency hopping designs. Radios using this technology are not allocated specifically to ground or flight applications.

D2) If using 50 or 53 megahertz does the operator have a valid Technician or higher (General, Extra, Advanced) ham license in his possession?

D3) Did the operator range check his equipment? A range check is performed by collapsing the transmitter antenna and walking away from the model while an observer watches the function of one of the radio controlled channels. Modern receivers will generally operate without glitches or loss of control between 75 and 100 feet from the transmitter.

D4) Does the operator have authorization to use the frequency? There are discrete frequencies within the 27, 50, 53, or 72 megahertz bands that must be deconflicted. “Clothespin” frequency control and/or radio impound may be used to prevent unauthorized frequency use. Radios using 2.4 gigahertz frequency hopping or spread spectrum technology generally do not require frequency deconfliction. Find out from the event director or RSO what the frequency control procedures are.

D5) Is the radio (transmitter) compliant with AMA narrow band guidelines? Older radios will have gold stickers. All radios built since 1991 will comply with the narrow band requirement even if they do not have gold stickers.

D6) Are receiver antennas protected from breakage (not flopping freely, do they have strain relief)?

D7) If other transmitters (e.g. amateur television) are onboard the model has the modeler verified proper operation and range of his radio control equipment with the other transmitters operating?

Items E1 through E6 concern the use of electronic systems for parachute or staging operations.

E1) Ask if electronics are used for control functions in the model (e.g. for parachute deployment, staging). Examine the electronics for items that may dislodge (e.g. motor igniters) or break during flight. Electronic systems should be safed (not capable of operation) when presented for safety check-in.

Are heavy items, e.g. batteries, adequately supported to prevent coming loose from “g” loads. Are switches and relays oriented to prevent unintended operation from model acceleration (and deceleration)? Are “g’ switches properly oriented to function from acceleration loads? Is the compartment vented to allow outside air pressure sensing for barometric sensing electronics?

How did the modeler verify the functionality of his electronics? When was the last time the electronics were checked? Are the batteries fresh? If the recovery is altimeter based, has the modeler verified its operation, e.g. in a bell jar with a vacuum pump? If transmitters (e.g. amateur television) are onboard the model has the modeler verified proper operation of his electronics with the transmitters operating?

E2) Does the modeler expose himself or others to accidental discharge during arming/disarming the electronics? Do the electronics indicate whether or not they are armed? Keep in mind that operating onboard transmitters, e.g. amateur television, may affect the operation of other airframe electronics.

E3) Does the modeler have a checklist or reminder to arm the system prior to flight and disarm the system upon landing?

E4) If the modeler is using self-made ejection charges ask how he estimated the amount of black powder to use. A simplified equation used to calculate the amount of black powder in grams is C x D x D x L = grams of black powder. Use 0.004 as a value for C corresponding to a 10 psi (pounds per square inch) chamber pressure. C for higher pressures can be calculated by (0.004 x Y/10) where Y is the desired chamber pressure. D is the diameter in inches and L is the length in inches of the pressurized compartment.

Ask the modeler if he has ground tested his separation system. If the amount of black powder used seems minimal or excessive ask how the modeler determined how much powder to use.

(The above information is from the following URL: https://www.info-central.org/?article=303)

Ask if the modeler is using black powder, Pyrodex, or some other propellant type powder. Alternatives to black powder may not produce the same result when used in the same manner as black powder. Pyrodex, for example, is not as easy to ignite as black powder and is not as powerful as black powder in low confinement conditions (such as those present in a recovery deployment system). If an alternative powder is used ask if it is the material used for the ground testing.

(The above information is from a note to the editor written by Mr. Larry Mills in the May 2000 issue of High Power Rocketry.)

E5) If timers initiate recovery system deployment how was the delay time calculated? Did the calculations reflect the motor being used and the actual weight of the model? Is the coefficient of drag used for the calculation reasonable for the model?

Items F1 through F3 concern the launch pads. Modelers will occasionally use their own launch pads to support their models. Verifying the below items during check-in removes a potential burden from the RSO.

F1) If tower launchers are used verify that the model cannot “escape” from between the rails.

F2) Verify that modeler supplied launchers have blast deflectors to prevent exhaust impingement on the ground.

F3) If the modeler is using his own launch pad is it sufficiently sturdy and does it have a large enough “footprint” to provide a stable launch platform, especially for heavier models?

Range Safety Officer Guidelines:

Items G1 through G17 concern the basic range setup and facilities. The RSO should inspect the range setup prior to the start of launch activities to identify potential safety issues. The RSO also needs to be familiar with the location of safety equipment, e.g. fire extinguishers, first aid kit, and telephone.

G1) Is a means of measuring wind speed or getting weather reports available? “Turbine” style wind velocity meters are available starting around $100.00. These units read quickly and accurately (including gusts). The use of “venturi” style wind velocity meters is discouraged because these meters are affected by static and contamination.

G2) Do all launch pads have blast deflectors to prevent exhaust impingement onto the ground? Are launch rods securely fastened to the launch pad to prevent lofting of the launch rod with the rocket? Are the launch rods unbent and clean to minimize the likelihood of a rocket binding on the pad?

Do the launch pad numbers match the numbers on the launch controller? Mismatches may allow confusion regarding which pad is active and cause the launch of the wrong model.

Are launch pad numbers visible from all directions? Visibility allows individuals to determine if they are near “hot” pads if they are approaching from outlying areas.

G3) Does launch equipment have sufficient current output to light igniters with large current demands? Clusters are a concern because multiple igniters in parallel will draw more current than single igniters.

G4) Is the launch controller “flashbulb safe”? Some igniters, e.g. flashbulbs and electric matches, have very low current requirements for ignition. Launch equipment, which is not flashbulb safe, will ignite these igniters with the continuity current flow. Continuity currents of 10 milli-amperes or less are generally considered flashbulb safe. This is a general guideline because there are no specified “no-fire” currents for flashbulbs. If a question exists about the safety of the launch control equipment a representative igniter (without motor) should be tested for the possibility of accidental ignition.

G5) Is the ground cleared of all flammable materials around the launch pad? Minimum clear distances are 50 feet for “H” through “J” motors, 75 feet for “K” motors, 100 feet for “L” motors, and 125 feet for “M” through “O” motors. Is the clear distance increased by 50% if rocket motors utilizing titanium sponge (“Sparky” motors) are expected?

G6) Are launch pads located away from personnel per the distances specified in the safety codes? Are barriers, e.g. flag lines, in place to prevent entry into launch areas? Is pad access planned to minimize personnel crossing launch control wiring or approaching other “hot” pads.

If a mass launch of 3 or more high power rockets is being performed, is the safe separation distance the lesser of the complex rocket minimum distance for the total launch impulse, 2000 feet, or 1.5 times the highest expected altitude?

G7) Is the launch site sufficiently large enough for the power classes being flown? Refer to the High Power Safety Code for minimum field size requirements. Is the launch area the required distance from the edge of the site and/or roads and occupied buildings. Will the model trajectory cause models to land in spectator or non-participant areas? Remember that fin stabilized rockets will weathercock into the wind. Consider the trajectory possibilities for models which have recovery failures and those that drift in the wind after recovery. Where possible, locate spectator, preparation, and parking areas away from the likely impact points for recovery failures.

G8) Is fire fighting equipment available? Water is the preferred fire fighting agent for grass fires. An A:B:C: dry chemical extinguisher should also be available to fight electrical or fuel fires (e.g. gasoline from a generator). Does a fire fighting plan exist? At a minimum, all personnel on the range should be told to stop whatever preparations or launch activity they are doing and assist in containing a range fire.

G9) Are battery terminals protected from accidental shorts, which can cause a fire or battery explosion? If used, are 110 VAC supplies protected to prevent electrical shock (e.g. ground fault interrupter). Extension cord connections should be raised above wet grass. The use of 110 VAC power should be suspended in the event of rain.

G10) Is a first aid kit available? Are emergency telephone numbers for the power company, fire, and ambulance easily available? Is a phone nearby to call for assistance?

G11) How are participants and spectators made aware of an incoming model? Public address announcements work but consider a siren or air horn as a heads up signal.

Some ranges use a broadcast band FM transmitter to allow reception of countdowns and range head information. Consider setting up inexpensive FM radios at the edges of the range area to make announcements more audible in those areas.

G12) Is smoking controlled? Safety codes prohibit smoking, open flames and heat sources with 25 feet of high power rocket motors. Be aware of other flammable materials on the site where smoking, open flames, or heat sources may be a hazard (catalytic converters on cars have started fires when the vehicle is parked on high grass). Are “butt” cans available to prevent discards of lit smoking materials on the ground?

G13) If applicable, has the FAA been given proper notification of rocket launch activities? Per FAR 101, Part 101.27, Air Traffic Control (ATC) at the facility nearest to the launch shall be notified of launch operations for Class 2 rockets 24 to 72 hours in advance of the start of launch operations. Information that may be required by the ATC when performing the notification includes:

(a) The name and address of the operator; except when there are multiple participants at a single event, the name and address of the person so designated as the event launch coordinator, whose duties include coordination of the required launch data estimates and coordinating the launch event;

(b) Date and time the activity will begin;

(c) Radius of the affected area on the ground in nautical miles;

(d) Location of the center of the affected area in latitude and longitude coordinates;

(e) Highest affected altitude;

(f) Duration of the activity;

(g) Any other pertinent information requested by the ATC facility.

Is a copy of the waiver/authorization available on the launch range? Do all participants know the waiver limits? Is a contact point and method (e.g. cellular phone) available to the FAA in the event of a problem?

G14) Does the RSO have a means of clearly and consistently communicating with the launch control officer (LCO)? The communications must be clear to allow coordination of pad access and launch permission.

G15) Are binoculars available to allow the RSO to better assess the safety of a airborne rocket?

G16) Where are models with electronic systems prepared/armed for flight? Typically, igniter installation and arming is performed at the launch pad. For models requiring more extensive preparation, is there a preparation/arming area positioned and/or isolated from event participants to minimize exposure in case of inadvertent activation of an upper stage or recovery system? Radio emissions can cause inadvertent electronic system activation. Are any controls in place for the use of radio transmitters around electronic staging or recovery systems?

G17) Are participants and spectators warned of any general site hazards, e.g. snakes, gopher holes, and hazards from shared activities?

Items H1 through H7 concern activities immediately prior to the launch of a rocket. The RSO should be constantly scanning the launch pad areas for personnel and skies for aircraft.

H1) Is the launch angle within 20 degrees of the vertical?

H2) Is the model stable on the launch pad? Verify that the model is not twisting around its launch lug in a manner that may cause binding on the launch pad. Verify that the model and launch rod are not “whipping” around in the wind. This may be indicative of too small a launch rod diameter. Does the launch rod look adequately long for the model on the launch pad? How close is the upper launch lug to the end of the rod? Many 1/4 inch launch rods are at least 4 feet long; many 1/2 inch launch rods are at least 6 feet long.

Special attention should be given to large models. In addition to launch rod observations, make sure that the launcher base is stable. Staking and/or sandbags are a method to improve launch pad stability.

H3) Are winds within safety code requirements (no greater than 20 miles per hour)? Staged models and models with large fin areas may weathercock significantly into the wind; consider the possible trajectories of such models before launch.

H4) Are spectators or modelers within the safe distance of the launch pad? Make sure that adjacent launch pad preparations are not too close to the active launch pad. Hold the launch until people are clear of the pads.

Minimize the number of people in the vicinity of a launch pad where a rocket is being placed for flight. Except for extreme circumstances, the number of individuals around a rocket being placed or removed from a launch pad should not exceed four people. Photographers should be asked to leave the launch pad prior to igniter installation and arming of rocket systems.

H5) Are the skies clear of aircraft? Ask for assistance from other launch participants to scan for aircraft. Has the tower or other FAA facility been notified of the launch if required by the waiver conditions?

H6) Is the model being launched a hybrid? Hybrid motors are more sensitive to ambient temperatures than solid rocket motors. Cold temperatures will significantly reduce performance as compared to a solid rocket motor. Consider giving launch priority to hybrid powered models because of their environmental sensitivity.

H7) Are required model electronics armed for flight? Are there any “Remove Before Flight” streamers hanging from the model? Does the modeler need to arm his electronics manually prior to launch; ask if he has done so? Are all umbilical and lanyard connections attached (or detached) as required for model operation?

Items J1 through J5 concern observations of the flight. The RSO should observe the model’s operation at least until the recovery system has fully operated and the rocket’s safe descent is verified. Even after verifying the rocket’s safe descent it should be periodically observed to ensure that its touchdown is not a threat to personnel or property.

J1) Are models penetrating the cloud cover? If models are penetrating the cloud cover there is a hazard to aircraft (and a violation of most FAA waivers). Identify the altitude where the cloud cover exists and modify the allowable power and weight requirements to prevent cloud penetration.

J2) Are models trajectories allowing models to land into spectator or parking areas? Adjust pad angles to prevent models from entering these areas. Do pad angles allow a ballistic flight to impact in non-occupied areas?

J3) Remember that staged models will have multiple pieces requiring recovery. Observe all pieces to verify that their recovery systems have deployed. Warn range personnel if incoming parts are a hazard.

J4) Models with electronic recovery systems may have multiple deployment events. A drogue parachute may be deployed at apogee and a main parachute may be deployed at some preset distance above the ground. Observe the model to verify that all planned recovery events occur. Warn participants and spectators not to handle a model that has not completed all planned deployment events because live charges and armed electronics may present a hazard. Only the model builder or people familiar with the rocket’s systems should handle a model with electronic deployment after a flight.

J5) Is there a common thread to any flight failures, e.g. a particular modeler, model, or motor? Notify the check-in officer to prevent potential problems from reaching the launch pad

Street: _______________________________ City: ____________________ ZIP: ______

Day Phone: (______)__________________ Evening Phone: (______)_________________

Email Address: __________________________________ High Power Cert. Level: _______

Training Documentation:

The following pages will document your progress in completing the safety officer training. Print your name and NAR number at the top of each page. Volunteer to assist in the safety check-in officer and range safety positions at the launches. You may have to coordinate with range officials prior to the launch to have a mentor assigned or to schedule a range shift. Opportunities to perform training in the range safety officer or safety check-in officer positions may be accepted in any order; there are no requirements to complete training in one position prior to training in the other position.

Have your mentor complete the training blocks as each requirement is met. The same mentor is not required for each training step. There is no time limit to complete the safety officer training; proceed at your own pace and as training opportunities occur. It is suggested that attendance at the larger regional meets or national events will provide the greatest exposure to different model types and different mentoring techniques. The variety of models and volume of flights at these events can improve the quality of the training experience and expedite completion of the training process.

Level 1 certified high power modelers, may perform the safety check-in officer or RSO duties on a NAR Level 2 or Level 3 high power range after completing this training program. The Level 1 modelers will be required to complete the Level 2 high power certification written exam to perform those duties. They may credit the accomplishment of this exam towards Level 2 certification. The Level 2 exam question pool and tests may be requested from the address listed below.

Upon completion of the training requirements make a copy for your own records. Forward the completed forms (only those pages with mentor signoffs) to NAR Headquarters. Your NAR headquarters records will annotated to indicate completion of the safety officer training program. A revised sporting license will be issued to show completion of the training program. Questions and comments on this program can be answered by a letter to the above address, via email at 103056.621@compuserve.com , or via telephone at 520-296-1689

Individuals signing in the spaces below certify that the individual being trained has performed the required activity and demonstrates an understanding of the information provided to perform the task.

>> SAFETY CHECK-IN OFFICER TASKS <<

High power model check-ins: Each of the following items may be signed off after completing the check-in of Level 1 (“H”, “I”) or Level 2 (“J”, “K”, “L”) powered models. Items A1 through A9, B1 through B8, C1 through C6, and F1 through F3 provide guidance for these tasks. Ditto marks (“‘ “”) may be used if information is the same as the previous line.

| Task Number |

Mentor’s Name (printed) |

NAR/TRA Number |

Cert. Level |

Date |

Location City/State |

Motor & Remarks |

| 1 | ||||||

| 2 | ||||||

| 3 | ||||||

| 4 | ||||||

| 5 | ||||||

| 6 | ||||||

| 7 | ||||||

| 8 | ||||||

| 9 | ||||||

| 10 | ||||||

| 11 | ||||||

| 12 |

Models with electronic deployment/staging systems check-ins: Each of the following items may be signed off after completing the check-in of a model containing electronic staging or recovery systems. Items D1 through D7 and E1 through E6 provide additional guidance for these tasks. Ditto marks (“‘ “”) may be used if information is the same as the previous line.

| Task Number |

Mentor’s Name (printed) |

NAR/TRA Number |

Cert. Level |

Date |

Location City/State |

Motor & Remarks |

| 13 | ||||||

| 14 | ||||||

| 15 |

>> RANGE SAFETY OFFICER TASKS <<

High power range safety review: Each of the following items may be signed off after completing the pre-launch and flight range safety review for high power (“H” through “M”) models. Items H1 through H7 and J1 through J5 provide guidance for these tasks. Ditto marks (“‘ “”) may be used if information is the same as the previous line.

| Task Number |

Mentor’s Name (printed) |

NAR/TRA Number |

Cert. Level |

Date |

Location City/State |

Motor & Remarks |

| 1 | ||||||

| 2 | ||||||

| 3 | ||||||

| 4 | ||||||

| 5 | ||||||

| 6 | ||||||

| 7 | ||||||

| 8 | ||||||

| 9 | ||||||

| 10 |

>> LAUNCH SITE EVALUATION <<

Complete the launch site evaluation items listed below. It is preferred that the evaluation be performed prior to the start of the day’s launch activity to avoid interference with model launches. Discuss “No” answers with the mentor to determine why a “No” answer is acceptable. Refer to guidelines G1 through G16 for additional information.

| Refer to item: |

Description |

Yes |

No |

| G1 | Is a means of measuring wind speed or getting weather reports available? | ||

| G2 | Do all launch pads have blast deflectors? Are launch rods securely fastened to the launch pads? | ||

| G3 | Does launch equipment have sufficient current output for high current ignition requirements (e.g. clusters)? | ||

| G4 | Is the launch equipment “flashbulb safe”? | ||

| G5 | Is the ground cleared of flammable materials around the launch pad? Are provisions made to water down the area to prevent fire? | ||

| G6 | Are launch pads located away from personnel per the distances specified in the safety code? Are barriers in place to prevent unauthorized entry into the launch areas? Is pad access planned to minimize launch personnel from crossing launch control wiring or approaching “hot” pads? | ||

| G7 | Is the launch site sufficiently large per the safety code? Is the distance from the launchers to the site edge, roads, and occupied buildings sufficient? Will the model trajectories avoid spectator or non-participant areas? | ||

| G8 | Is fire fighting equipment available? | ||

| G9 | Are battery terminals protected from accidental shorts? Are 110 VAC supplies protected to prevent electrical shock? | ||

| G10 | Is a first aid kit available? Are emergency telephone numbers for fire and ambulance easily available? Is a phone nearby to call for assistance? | ||

| G11 | Is there a way to make participants and spectators aware of an incoming model? | ||

| G12 | Is smoking controlled? Are “butt” cans available to prevent discards of lit smoking materials on the ground? | ||

| G13 | If applicable, is the FAA waiver activated? Is a copy of the waiver available on the launch range? Do all participants know the waiver limits? Is a contact point and method available to the FAA in the event of a problem? | ||

| G14 | Does the RSO have a means of clearly and consistently communicating with the launch control officer? | ||

| G15 | Are binoculars available to allow the RSO to better assess the safety of an airborne rocket? | ||

| G16 | Is an electronics preparation/arming area provided to minimize the danger from an inadvertent activation of an upper stage or recovery system? |

Mentor’s Name, NAR No. (printed): ______________________________________________

Cert. Level: _____ Date: _________ Location (City, State): __________________________